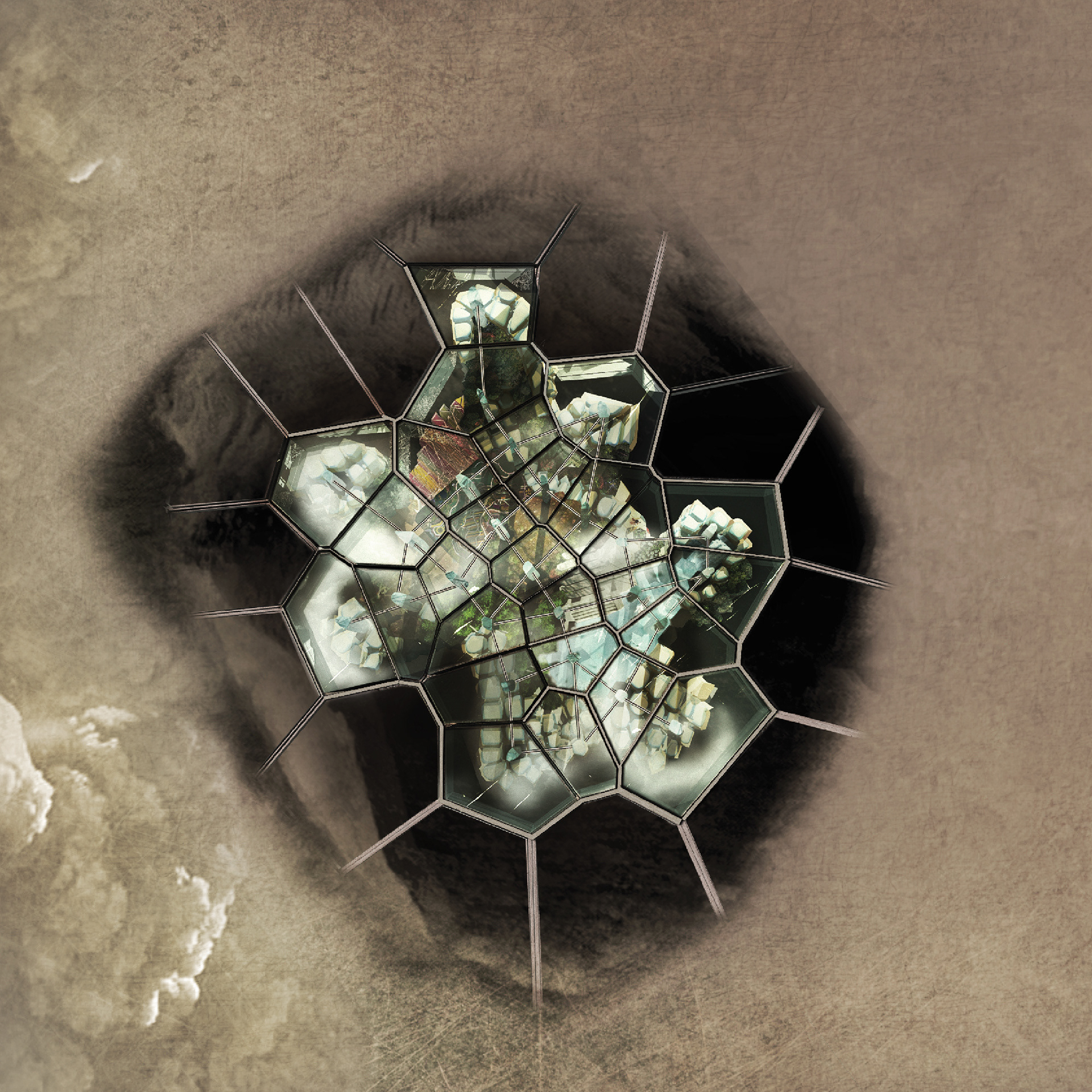

Ideal transformable, deployable, transportable, and smart housing is a current issue of our world, where people tend to explore and to discover places. Although the issue looks complicated, it is, in fact, a simple architectural problem that needs enough technical and technological supports.

Scissor joint structures have always been there for deployable architecture forms. The simple properties of such a chain reaction mechanisms enable the free extension of the form. Limits of such a free movement are the constant arbitrary changes in the width of the structures, while the stretching of the form is our primary goal.

The following is a winning project by Tiny house competition, and as the team leader, I designed and produced design documents and renderings.

Scissor joint structures have always been there for deployable architecture forms. The simple properties of such a chain reaction mechanisms enable the free extension of the form. Limits of such a free movement are the constant arbitrary changes in the width of the structures, while the stretching of the form is our primary goal.

The following is a winning project by Tiny house competition, and as the team leader, I designed and produced design documents and renderings.

Scissor joint properties

Scissor Mechanism Behavior

Structural Details

In a 6 time extension of the joints, a 40% width change takes place. This Value need to be supported with some form of ceiling/flooring. Holders can be used to maintain the width of structure and framing. Plus, help stabilize extension. After the expansion of the scissor joints, telescopic joints move along the Holders, forming the necessity basis for floor slabs to deploy. Studs of rolling grips each can take a specific rail to slide. Arrangement of rails on the sides of the project, making the smooth transition of the panels possible. The U shape telescopic joints with support the weight of the floors and transfer the weight to middle connectors, then this weight would travel to the both ends of the structure on the base pedestals. This would make the Transfer and transportation of the project much easier.

Different interior settings can be pre-programmed. Thus space would be reformed according to the needs and timings, so always the minimum and efficient space are available.

Transportation: The compact house can be easily transported with a pick-up truck any larger vehicle. On a semi-flat ground, the truck can jack and slowly move forward for the expansion to take place. The process can be programmed with a computer. The benefits of such a system are having your home the way you want it to always be with you, with the offer of plenty of views to catch from the same cozy home.

The expansion of scissor joints on top makes the same telescopic expansion possible, with different combinations. The bilayer ceiling enables the sustainable function of the project, according to season and day time. The first layer of the ceiling is a flexible transparent textile used in warm and desirable conditions as shades. The expansion process can be controlled by users. The second layer is a Monocoque panel shaped in a certain form to easily extend and also to protect the ceiling against climate changes. Multilayer cladding with a special geometry that allows interlocking of pieces. Connectors in the side of the rails balance the position of the panels and provide extra tension freedom for joints.

Exploded Diagram of Elements

Extension Process of the structure

Programmable Floor Plan